Torque Sensor Selection Guide

The full range of Torque Sensor covers 0-1NM to 0-60,000NM ranges

Torque Sensor has two types:

- 1. Static Torque Sensor

- 2. Rotating Torque Sensor.

Step No. 1 – select one from above.

Both of above types have different mounting configurations –

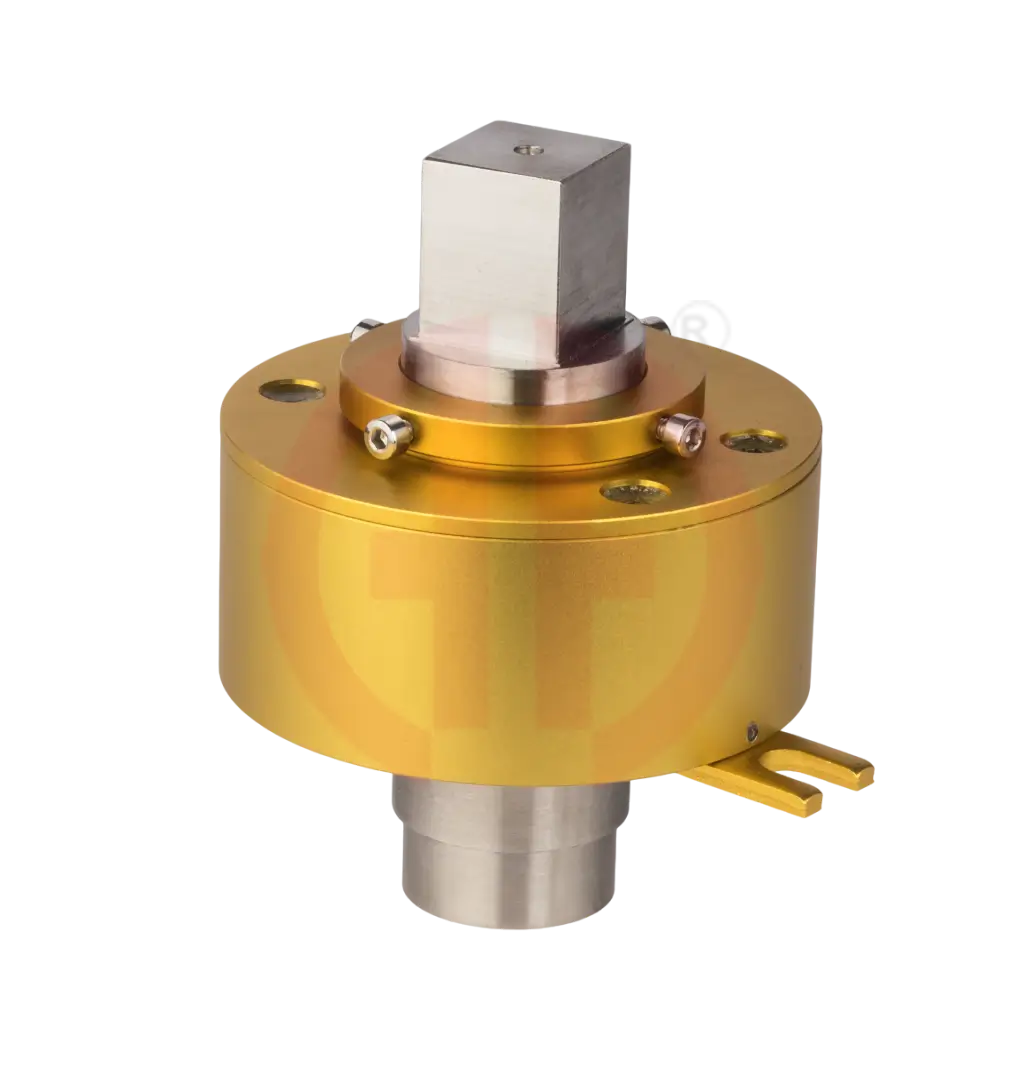

- Shaft type

- Flange type

- Square Drive type

Combinations of – Shaft and Flange, Shaft and Square Drive & Flange and Square Drive is also available.

Step No. 2 – select either of above.

Vide application supported configurations are offered as -

Static Torque Sensor –

Static Reaction Torque Sensor for Torque Measurement

Static Reaction Torque Sensor with Thrust Measurements – Dual parametric sensor –

two in one.

Static Reaction Torque Sensor with Angle Measurements – Encoder based – Dual parametric sensor

– two in one.

Rotating Torque Sensor

Rotating Torque Sensor for Torque Measurement

Rotating Torque Sensor with Thrust Measurements – Dual parametric sensor

– two in one.

Rotating Torque Sensor with Angle Measurements – Encoder based – Dual parametric

sensor – two in one.

Rotating Torque Sensor with RPM Measurements – Encoder based – Dual parametric sensor

– two in one.

Rotating Torque Sensor with RPM Measurements – Hall Effect Sensor based – Dual

parametric sensor – two in one.

Rotating Torque Sensor – Wireless Telemetry Type.

Step No. 3 – Select any one required from above.

Supporting Accessories – Mounting Hardware, Instruments and Software.

Step No. 4 – Decide if you need any of the supportive accessories.

Step No. 5 – Decide the torque capacity. If other parameters like – Angle, RPM,

Thrust are required, select the range.